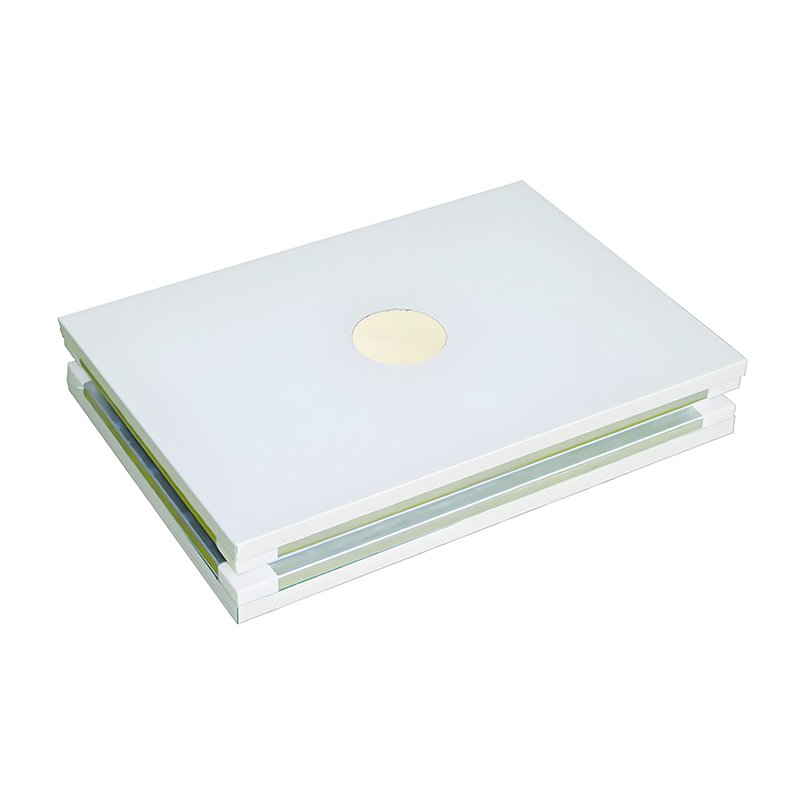

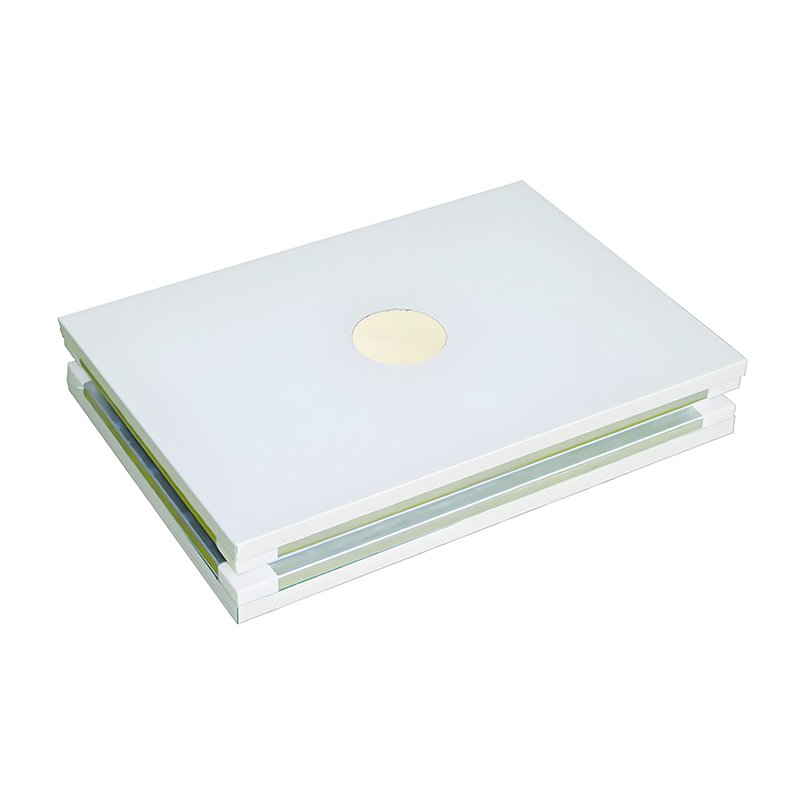

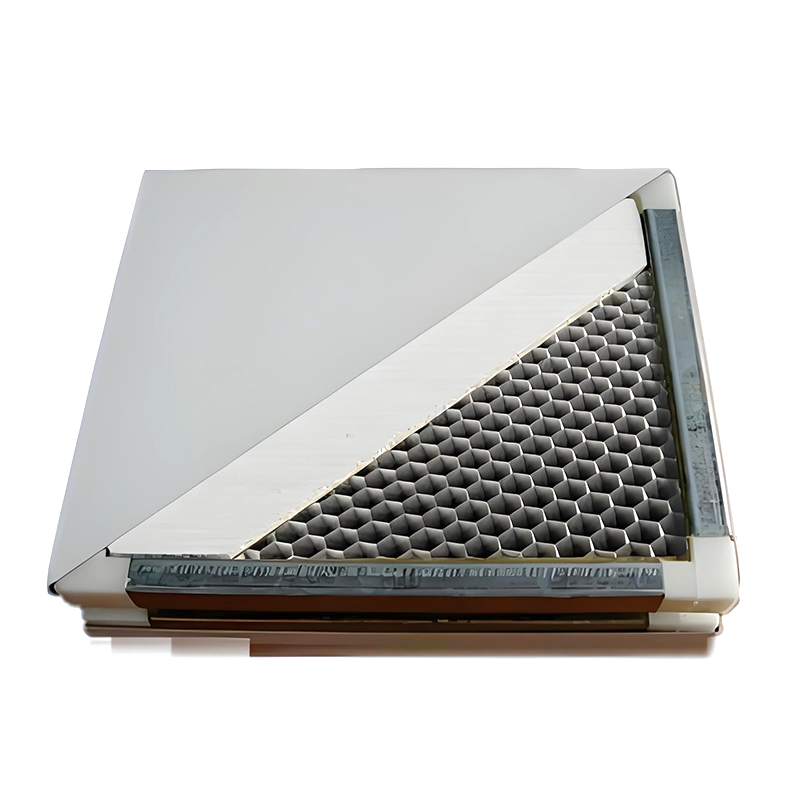

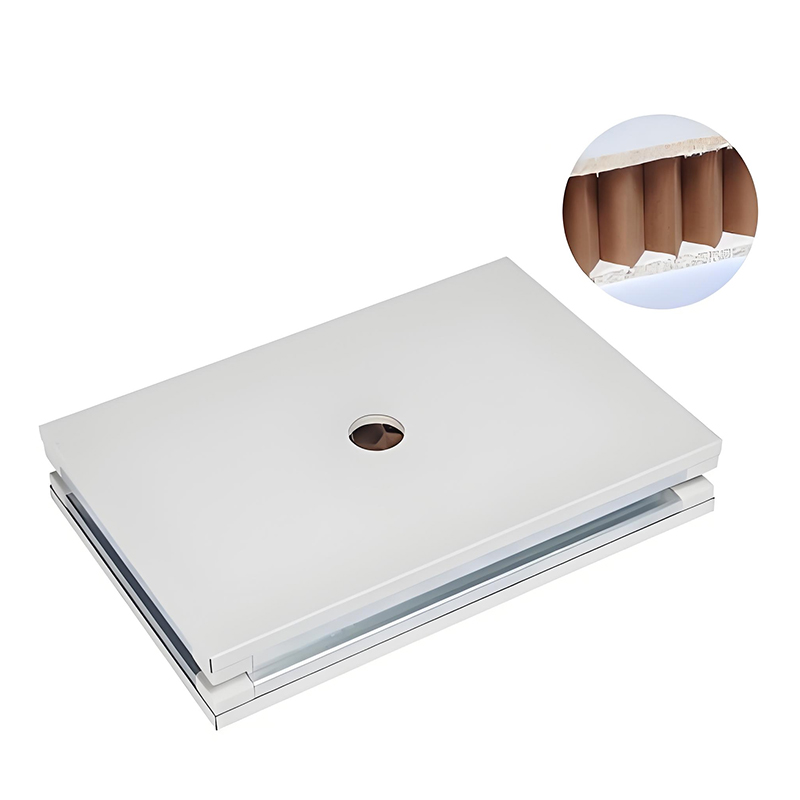

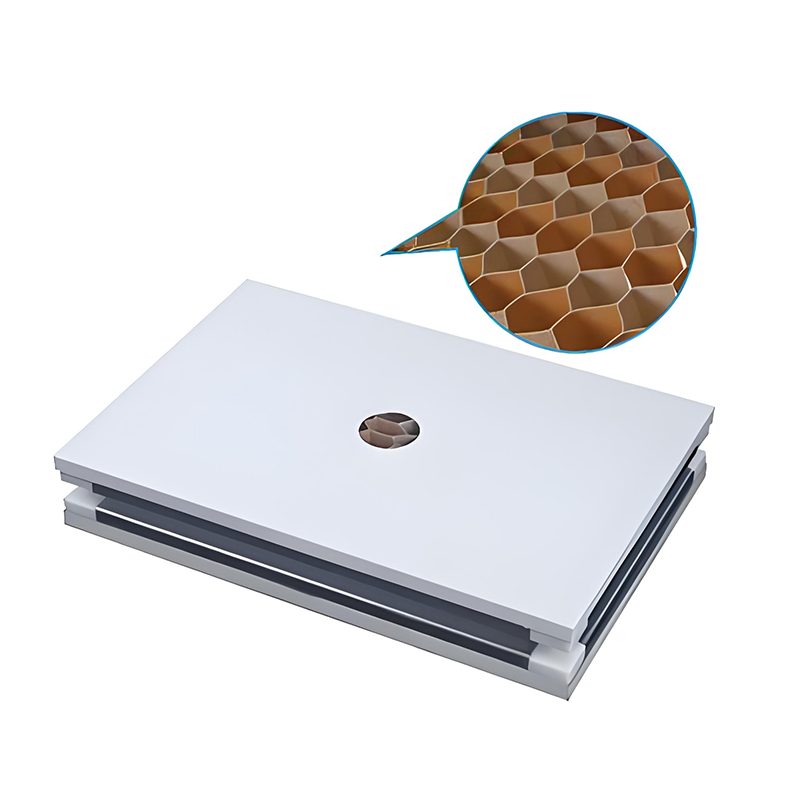

Hand made PU sandwich panel

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections: shape connection, male and female connec-tion,

The advantage of sandwich panels in cleanrooms lies in their ability to provide a highly controlled environment through features like excellent thermal insulation, smooth and easy-to-clean surfaces that resist contamination, and structural durability. They also offer quick installation, reducing construction time and costs while maintaining high standards of hygiene and safety required for sensitive environments.

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections: shape connection, male and female connec-tion,

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections: shape connection, male and female connec-tion,

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections: shape connection, male and female connec-tion,

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections:shape connection, male and female connec-tion, 3

Specification Length:as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections:shape connection, male and female connec-tion, 3

Specification Length: as per requirement, usually≤6000mmWidth: most common 1180mm, 1150mm, 980mm, customizableThickness: 50mm, 75mm, 100mmConnections: shape connection, male and female

Cleanrooms are highly controlled environments used in various industries to minimize contamination and maintain high standards of cleanliness.

The design and operation of cleanrooms are tailored to the specific needs of each application, with varying classifications based on the level of cleanliness required.

Partner with AirTech Purifying, the leading provider of comprehensive cleanroom solutions, specializing in engineering design, consulting, manufacturing, and construction.

At AirTech Purifying, we are dedicated to accelerating your success with our end-to-end purification services. Discover how our engineering expertise can enhance your pharmaceutical, medical, or food preservation operations.